- Electrical machines play a vital role in energy conversion and are closely connected to power electronics.

- Electrical drives are essential components in industrial processes, bridging control signals with mechanical and electrical power.

Electrical Machines and Energy Conversion

Electrical Drives in Industrial Systems

Promotion of Electrical Machine Applications within IES

- Publishing high-quality technical papers in leading conferences and journals to share the latest research and advancements in electrical machines.

- Organizing conferences, special sessions, journal sections, and workshops to foster collaboration, knowledge exchange, and networking among researchers and industry experts.

- Creating strong connections between academic research and practical applications, ensuring innovations in electrical machines are effectively translated into real-world solutions.

- Providing tutorials and training programs for both academia and industry to enhance understanding of electrical machines and their applications.

Technical Publications

Conferences and Workshops

Bridging Research and Industry

Tutorials and Training

Trend and Current Electric Machine Applications

- Electric Vehicles

- Aerospace

- Wind Power

- Robotics

Trend and Current Electric Machine Applications

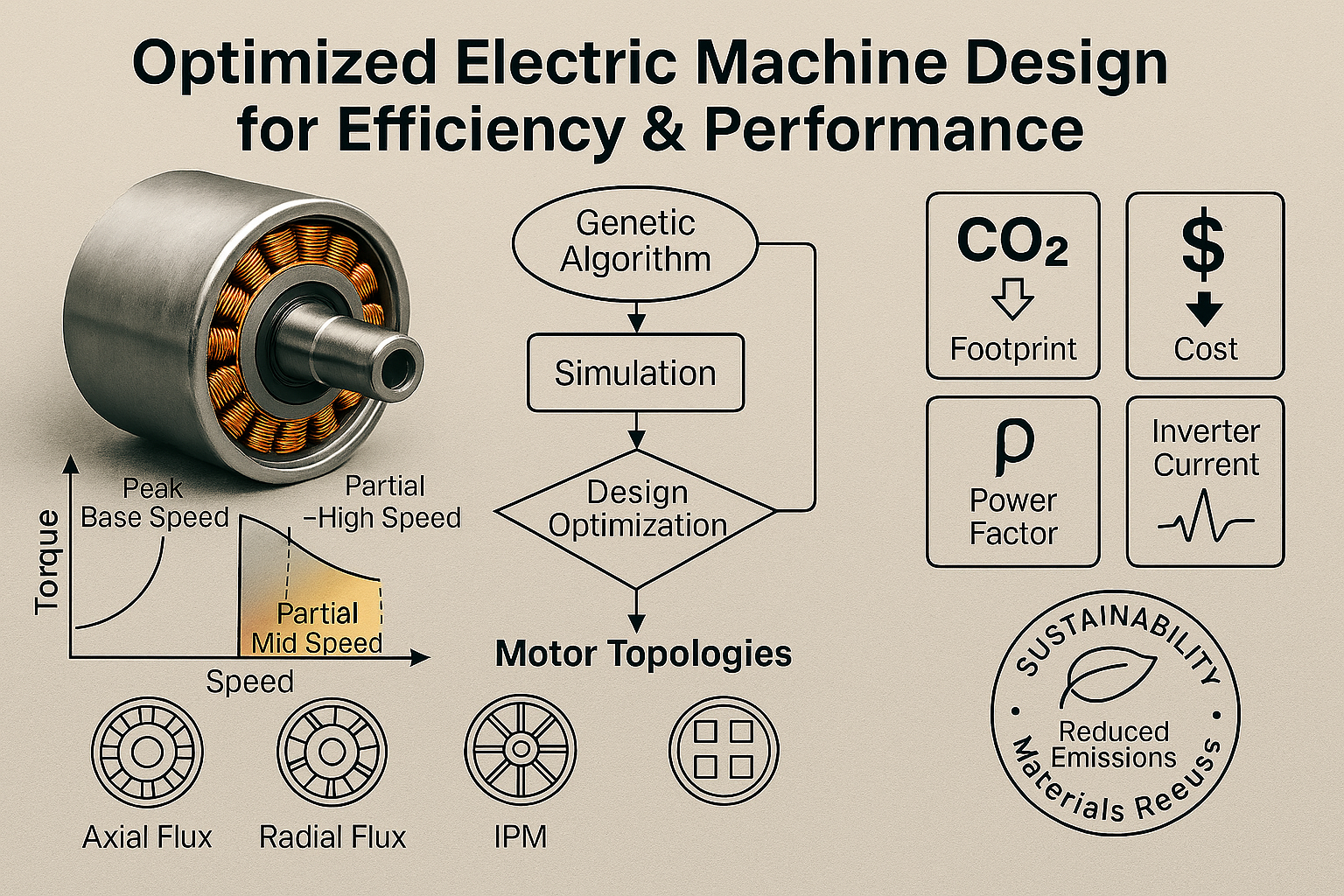

More efficient conversion systems require the optimization of electrical machine electromagnetic design to achieve specific performance levels (reduced torque ripple and increased efficiency and torque production), thermal and electrical design to obtain increased torque density, the integration of electrical machines with power electronics for traction applications to increase power density, and to implement new functionalities, such as integrated battery chargers.

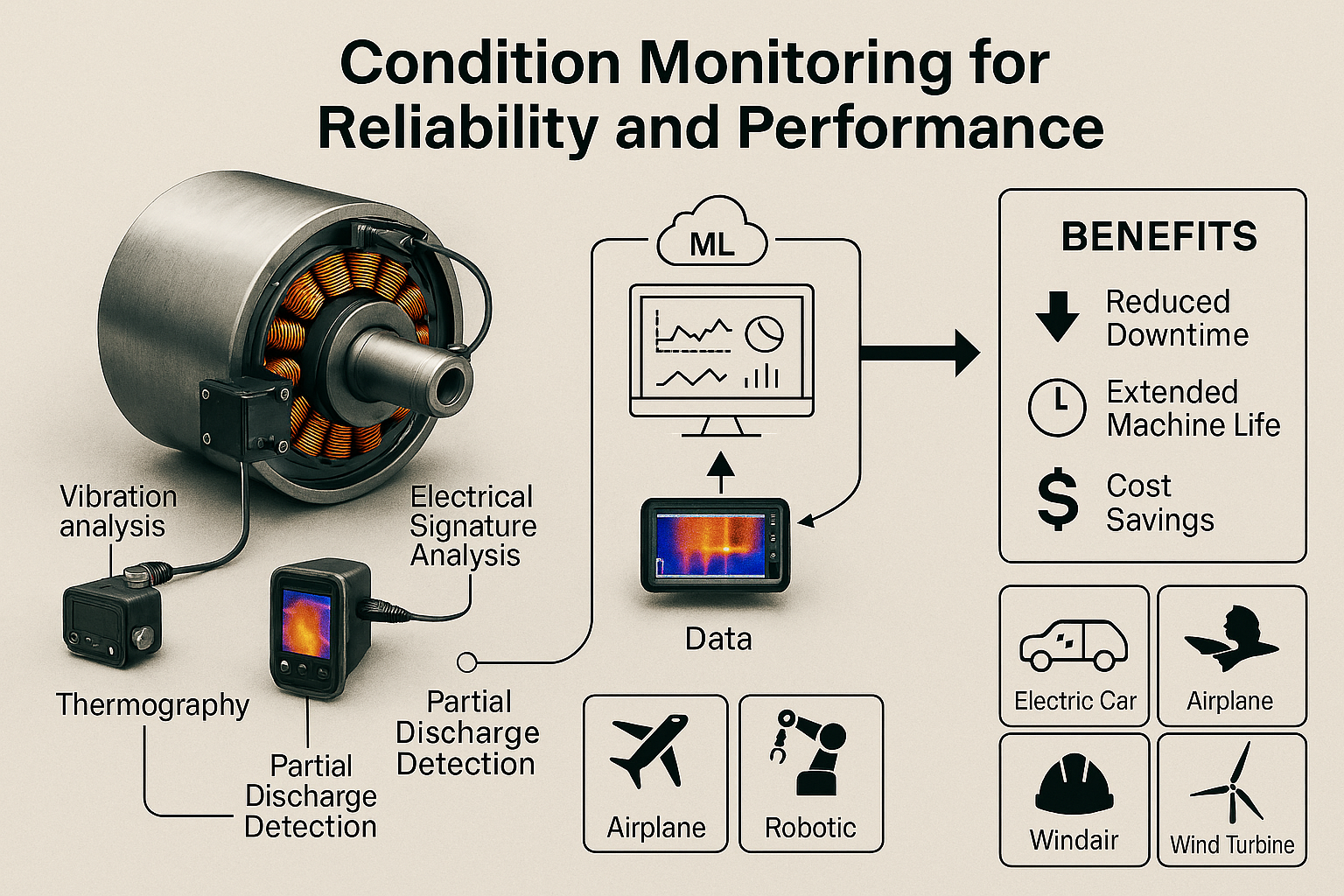

Condition monitoring and fault diagnosis and prognosis are critical to ensure the reliability and efficient operation of the energy conversion devices in those processes where they are involved.

Future research in the condition monitoring area will be mainly oriented toward the following areas:

(1) Remaining Useful Life Prediction

Developing advanced methods to estimate the remaining useful life (RUL) of motor components for proactive maintenance.

(2) Universal Diagnostic Algorithms

Designing diagnostic tools that operate effectively under all machine conditions, including transient states.

(3) AI-Based Fault Detection

Applying artificial intelligence to automatically identify motor faults without user intervention.

(4) Smart Sensor Integration

Using smart sensors to combine and analyze multiple parameters for complete motor health monitoring.

(5) Drive Train Condition Analysis

Extending diagnostic techniques to evaluate the motor drive train and other mechanical components.

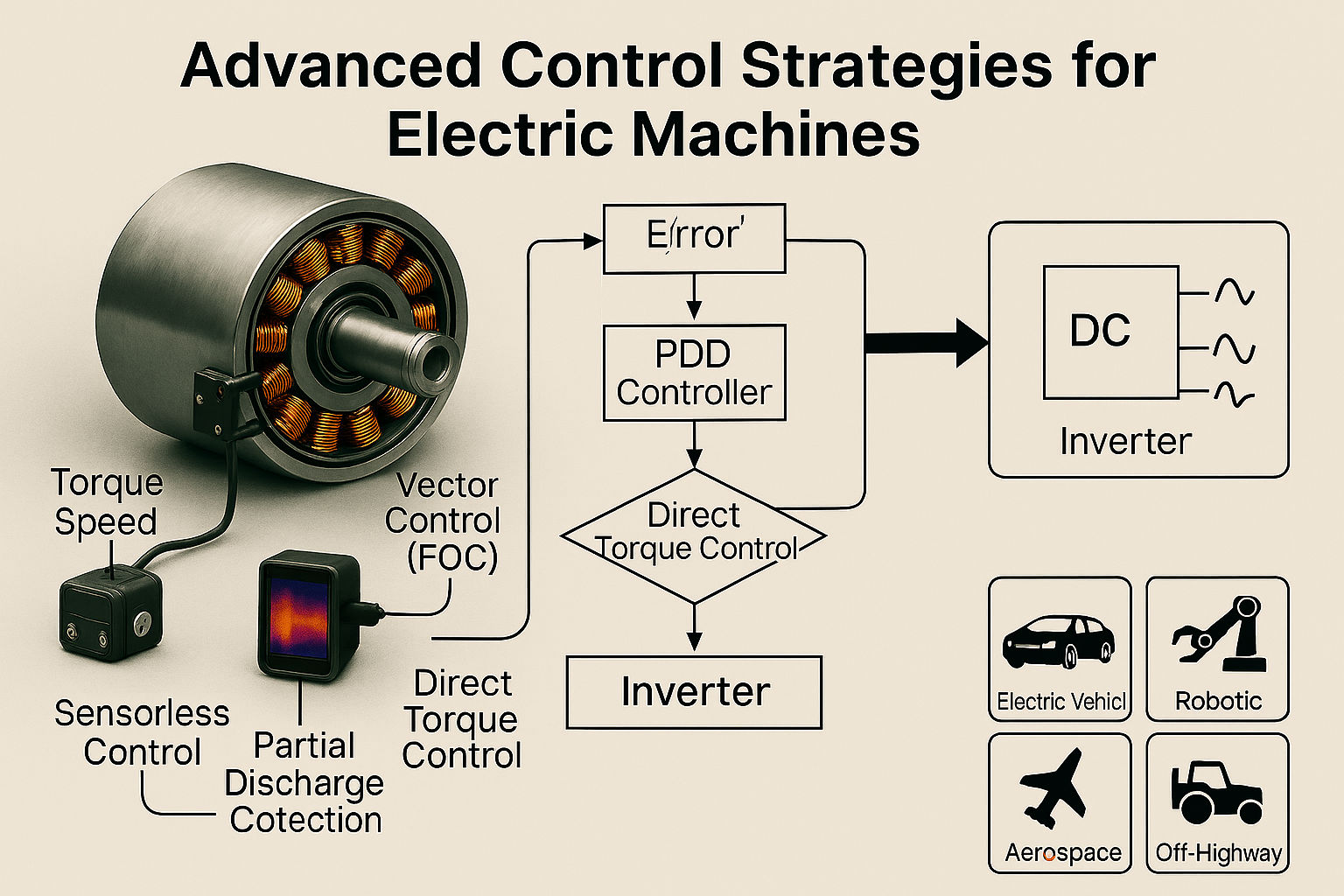

Speed Sensorless Control and Self-Commissioning

Modern systems integrate rotor position estimation directly into converter control, removing the need for external sensors. Combined with self-commissioning algorithms, these solutions enable easy, plug-and-play motor control.

Multiphase Drives and Fault-Tolerant Control

Using more than three phases reduces current per phase and improves reliability. Even if one phase fails, the system can keep running, making multiphase drives ideal for safety-critical areas like aircraft, traction, and large wind generators.

Predictive Motor Control

Model Predictive Control (MPC) offers excellent dynamic performance and simpler tuning compared to traditional control methods. With two main approaches—finite (FCS-MPC) and continuous (CCS-MPC)—MPC is becoming a key technology for industrial motor drives.